Here’s the process I’ve been using to add a silkscreen image to the exported STEP model from KiCad to Fusion 360. The steps are:

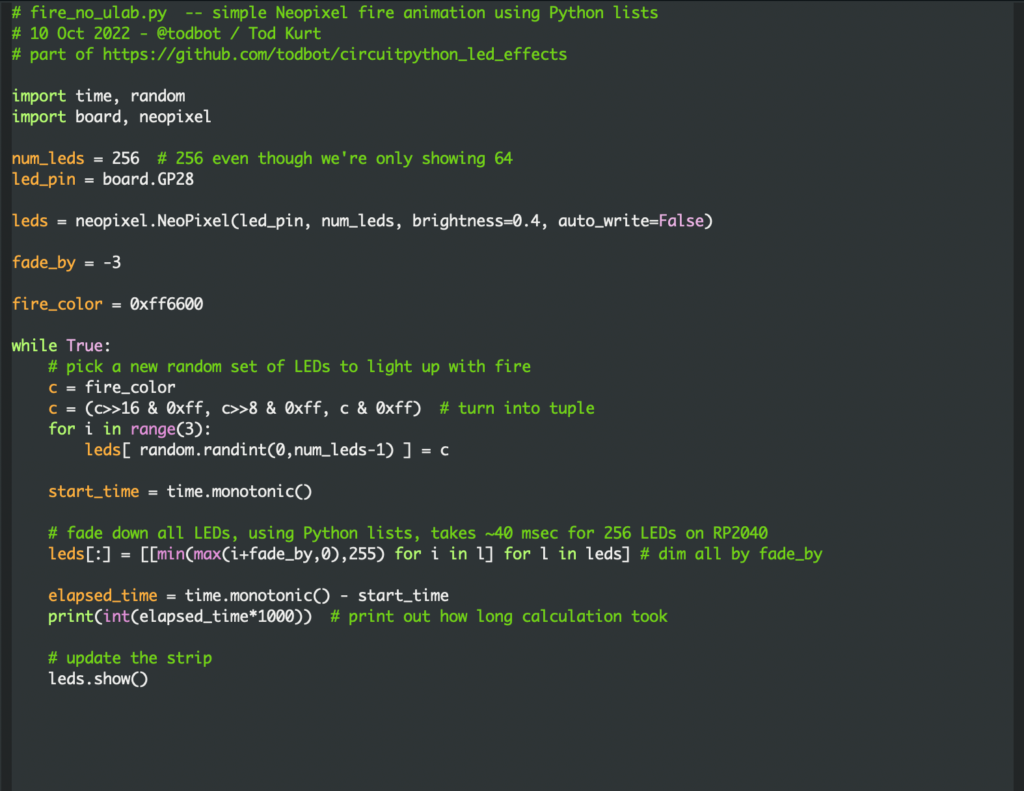

In KiCad PCB:

- File -> Export -> STEP to export 3D model of PCB w/ parts

- Open View -> 3D Viewer

- Press Z or Shift-Z to bright top or bottom silk face on

- Go to the 3D Viewer “Appearance Manager” and hide all parts

- Click File -> Save Current View as PNG

- Open up screenshot and crop to board edges

- Close 3D viewer – Open Inspect -> Board Statistics and note Board Size Width & Height in mm

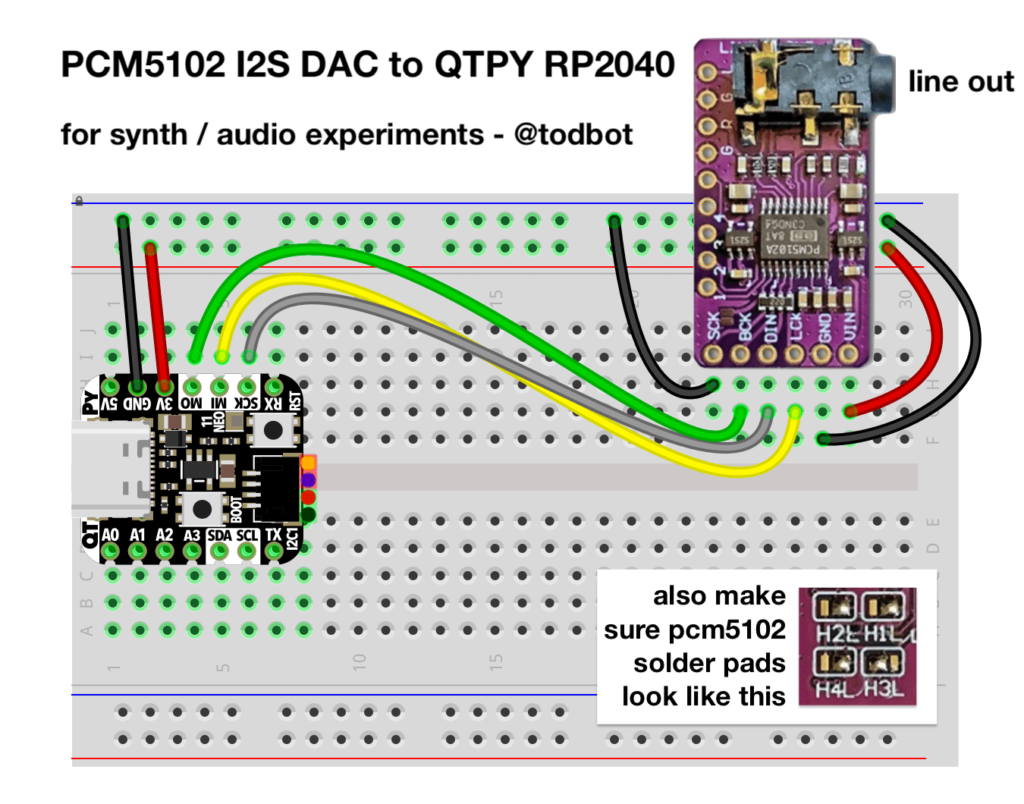

In Fusion 360:

- Upload STEP file

- Open uploaded file

- Click on the face of the PCB you want the silkscreen on

- Press A key to open up Appearance pane

- Click Apply To: Face

- In the “In This Design”, pick any square, right-click on it, choose “Copy to My Appearances”

- Go down to Library / My Appearances and right-click on newly added square

- Click Edit, this brings up another pane window.

- Click small down triangle to right of Color parameter

- Select “Image” and a file dialog will appear. Select your cropped silk image and “Open”

- Click down arrow again and “Edit Image…”, a new pane appears

- Under “Scale”, enter the board dimensions from above, make sure the aspect ratio lock is unchecked

- Under “Position”, make sure the “Offset” is -1/2 the board width and height

- Under “Repeat”, select “None” to turn off tiling

- Close that pane

- Back in the Material Editor, select “Apply To: Faces”

- Drag the new material you’ve created to the face of the PCB object in Fusion

- Done!