In many LED animations, you need to apply an operation to all LEDs as fast as possible. Often this is something like “fadeToBlackBy”, i.e. “dim all LEDs by a given amount”. There are some common effects you get by using “fadeToBlackBy” and one other action. For example: the Cylon effect is “Turn an LED on, Fade all LEDs toward black, Go to next LED, Repeat”. A simple firework simulation is “Turn on random LED, Fade all LEDs toward black, Repeat”.

Since I don’t come from a normal Python background, I’ve not used much Numpy. But I knew it was great for vector math. And I knew CircuitPython had a minimal version of Numpy called ulab it inherited from Micropython. Even though I’d seen the wonderful ulab learn guide that jepler did, the usefulness of numpy/ulab didn’t sink in. It was only when I was hacking on LED animation speedups did I re-stumble upon ulab. And am I glad I did.

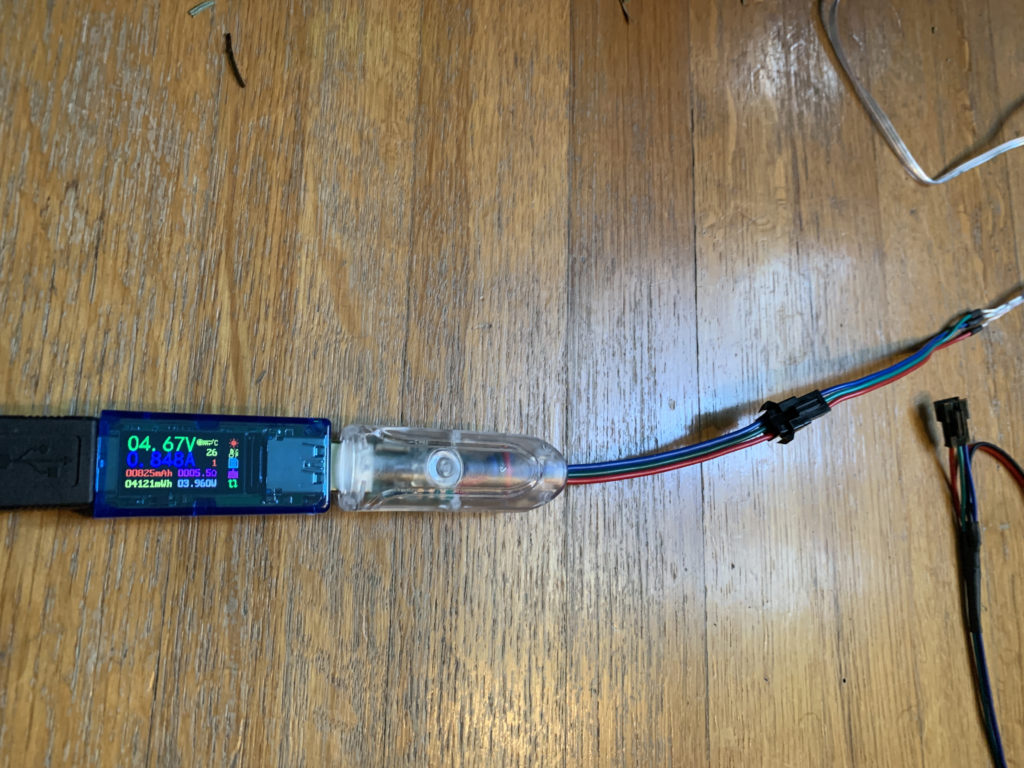

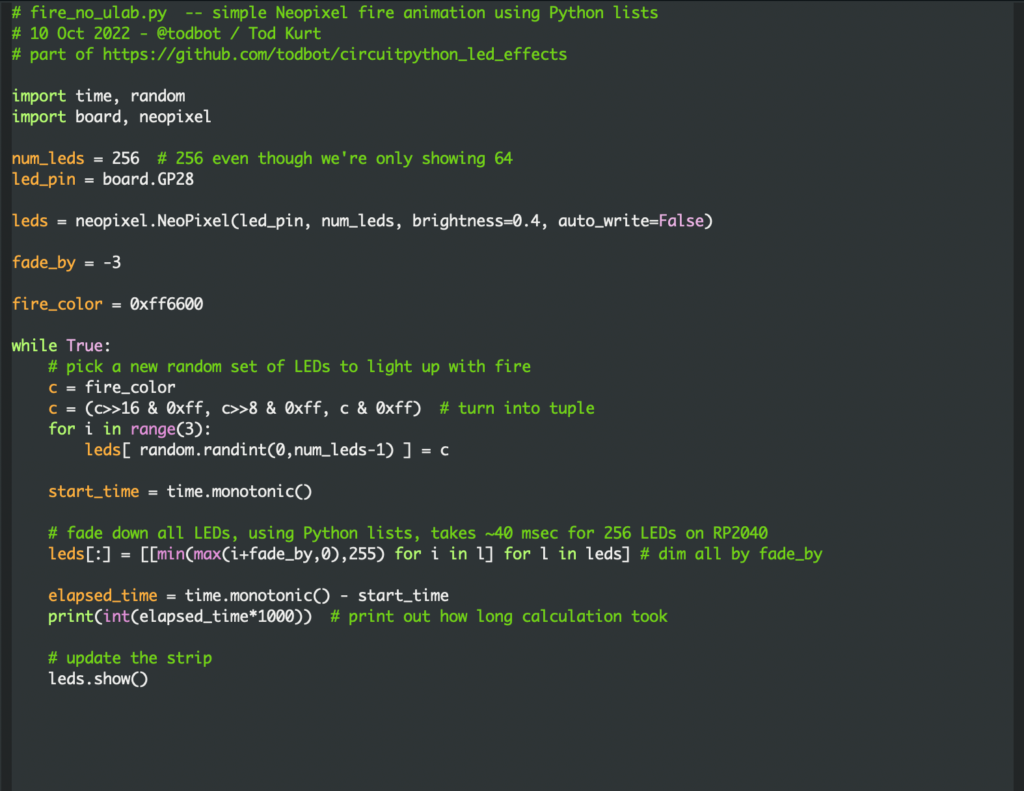

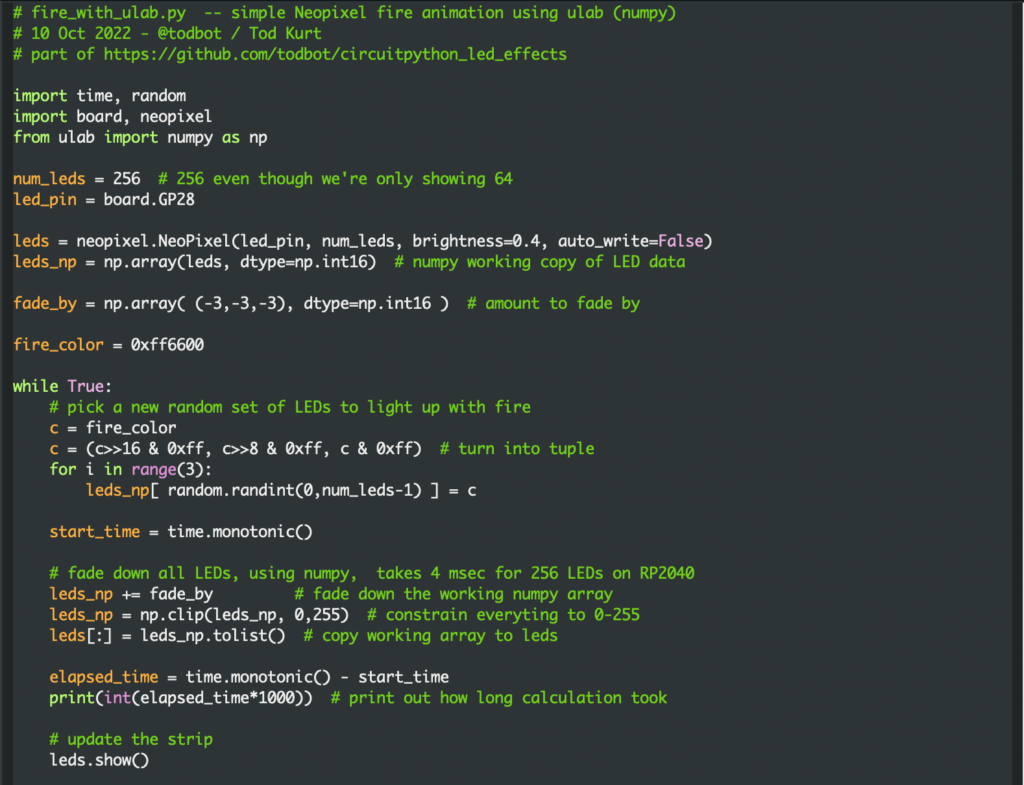

As a test with a simple fire animation (as optimized as I could make it in normal Python), the results with ulab are striking:

- fire_no_ulab.py: ~40 milliseconds per frame for 256 LEDs on RP2040

- fire_with_ulab.py: ~4 milliseconds per frame for 256 LEDs on RP2040

The general technique is to create a “working copy” of the LED data in a ulab array, and use ulab functions as much as possible to modify that working copy. Then at the last possible moment, copy the working copy data to the real LEDs object. It only adds a few lines of code to existing solutions and you get access to all these cool ulab array functions for LED effects! For instance, to constrain all RGB values of all LEDs to 0-255, this is a single line in ulab: leds_np = np.clip(leds_np,0,255). And it further cements my belief that any time you’re doing a for-loop on a large list in Python, you’re probably doing it wrong. :-)

Screenshots of functionally identical code, before / after:

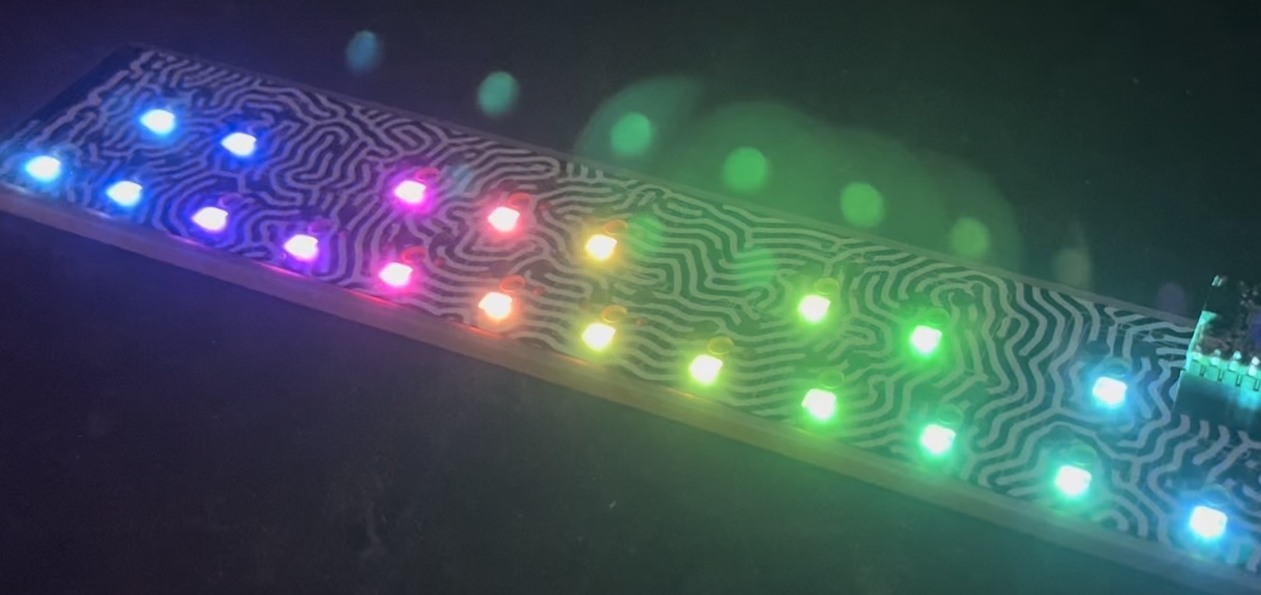

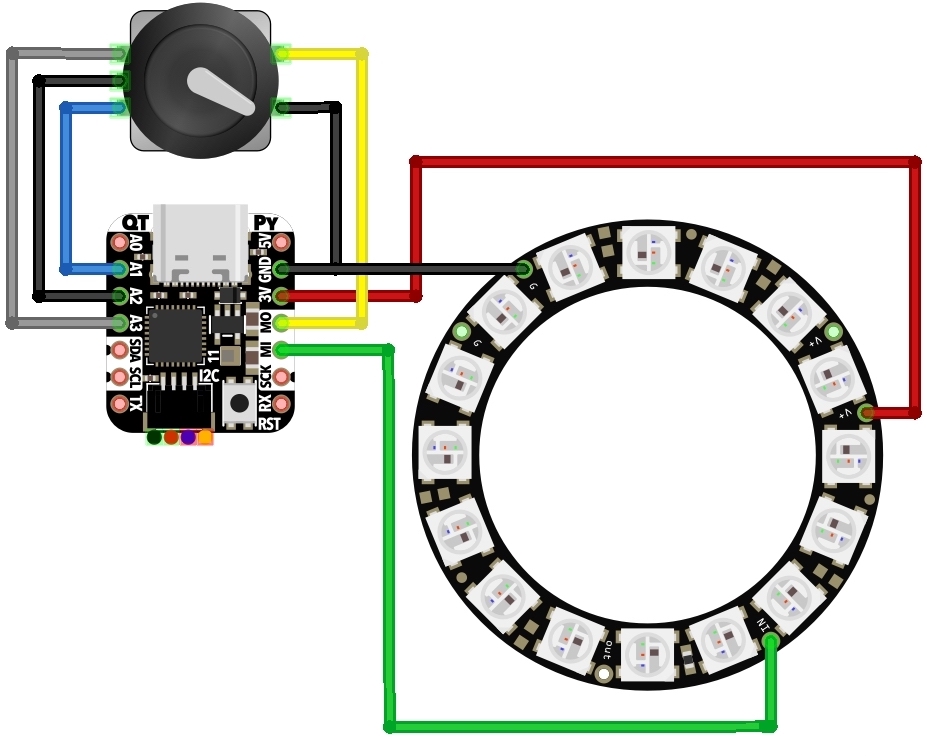

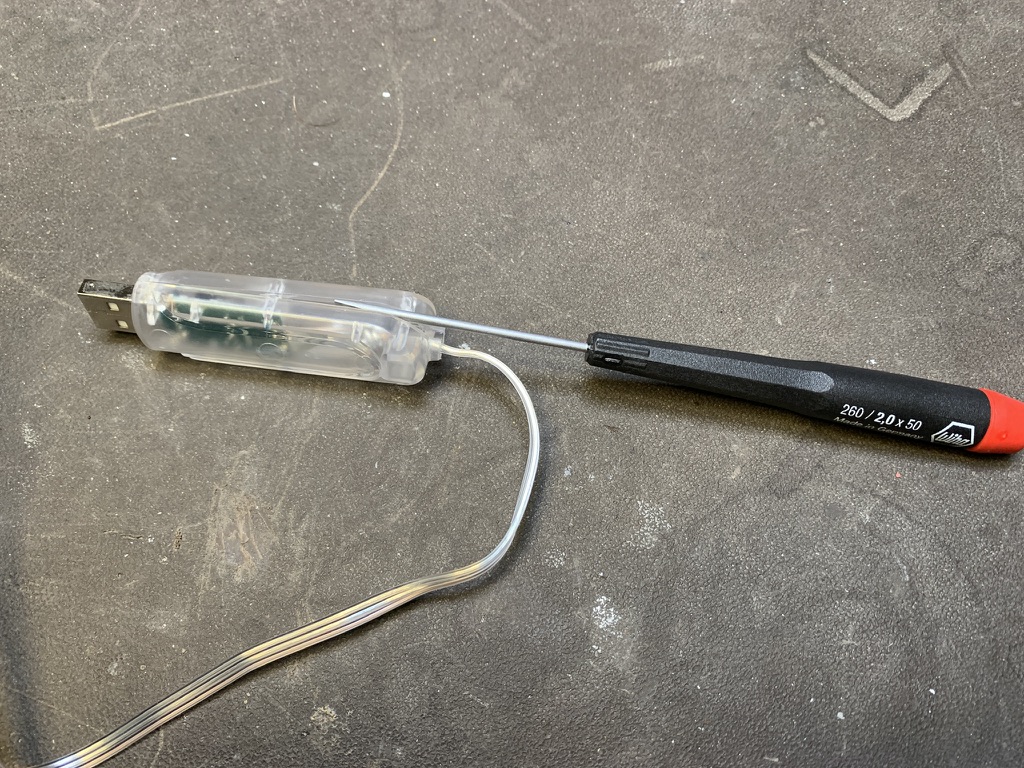

The video demo below shows the difference (also available on youtube). Each setup is identical, calculating for 256 LEDs even though only 64 are displayed. The “no ulab” case is perfectly usable if a bit choppy, but you lose ~36 milliseconds where you could be doing something else. (Like, for instance, these LED matrices are wired up in a serpentine pattern, so you need some math to unravel that if you want to draw shapes). The ulab version seems much smoother and more organic, at least to my eyes.

If you’d like to try this yourself, I’ve collected this code and a rudimentary “fire_leds” library that uses this technique in the repository: https://github.com/todbot/circuitpython_led_effects