After two years, I think I have my Replicator (apparently the first one shipped) finally working reliably to produce >1 hour prints. Thank you @iandanforth for asking if I had a description of the mods I did and prompting me to write this.

The Replicator has been a very frustrating product. After a few out-of-the-box failures, it worked great for the first week and then rapidly deteriorated. And a few months later, the Replicator 2 was announced and support for my product rapidly evaporated. Many of the things I print are small and take <15 minutes to print, so I’ve been dealing with a <30% success rate of printing, or using other 3d printers. But I think I’ve been slowly iterating towards a reliable Replicator.

Things I have done thus far (in roughly chronological order):

* Replaced heated build plate since the original was very non-flat

* Replaced both thermocouples with parts from Makerbot

* Installed new extruder design (eliminates all filament feed issues)

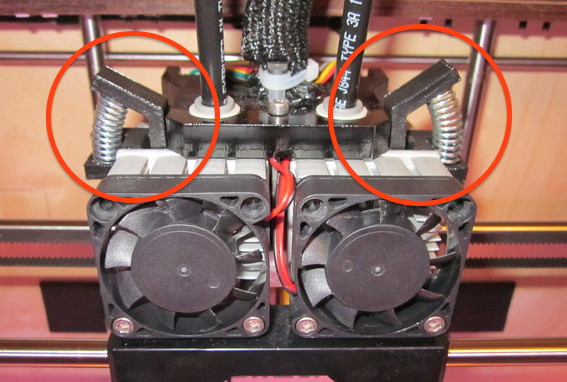

* Installed Bottleworks aluminum replacement arms

* Went to three-point bed leveling by removing one of the four leveling nuts.

The heated build platform and thermocouple issues were just bad original parts from Makerbot. I still sometimes have issues with “Heating Failure #3 my extruders are losing temperature. Check my connections.” on the right extruder, but I think that’s because of either a small crack in the replacement thermocouple or it just coming loose. I’m strongly considering using this Wanhao Duplicator replacement thermocouple if the problem comes up again. At least they terminate the thermocouple with a lug instead of trusting the assembler won’t crack it when tightening.

Assuming the basic mechatronics of the printer work, the most critical fix is the new extruder design. If you’ve ever experienced your Replicator stopping extruding or only partially extruding, it’s because the original mechanism to push the filament against the extruder motor sucked. This change was so important that Makerbot themselves retrofitted all Replicator 2s with it.

The next most critical mod is replacing those stupid plastic cantilever arms with something sturdier. Even at room temp, those arms exhibited considerable flex. Heat up the bed and the build plate would droop a few layers, causing so. many. failed prints. With the Bottleworks Aluminum arms, the bed is now rock solid.

I’ve also printed some little helper parts like extruder fan guards and leveling knob covers

Here’s some lists of other popular upgrades:

– Makerbot Users list – “Popular non-printed upgrades”

– EEWeb Gary’s blog – “Makerbot Replicator upgrades”

In general, be sure to poke around the Makerbot Users mailing list. It’s got useful tips and very knowledgable people.

From that and the (now discontinued) Makerbot Operators list, I’m just waiting for the day when the entire Replicator motherboard fries itself (another story, there are many) due to bad voltage regulator design. When that happens, not sure what I’ll do.

On the one hand, maybe get a steel Duplicator 4S, maybe a Lulzbot Taz 4 modded for 1.75mm filament, or maybe support the local guys and get a Bukobot.

2 Replies to “Makerbot Replicator mods I’ve done”